Products

Contact Us

Nantong Wanda Friction Material Co., Ltd.

Tel: +86-513-88725298

Fax: +86-513-88802154

Export Manager: Qiu Ruoyun

Email:sales@chnnanmo.com

Address: Longzheng Industrial Park, Hai'an High tech Zone, Nantong, Jiangsu

Clutch Facing

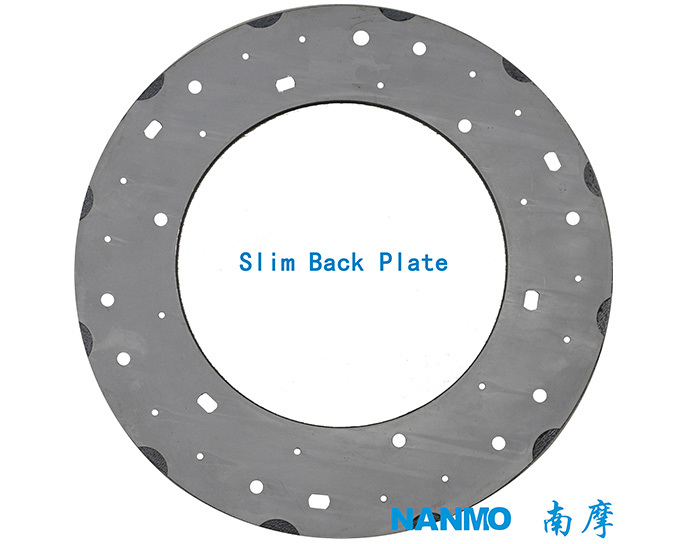

SBP friction plates are made by bonding thin steel plates on the back of the original friction plates, which can increase the rotational burst strength and prolong the service life. Especially suitable for trucks operating in harsh conditions and AMT trucks.

WDK828HB (Hybrid) is a friction material used for torque limiting shock absorbers in hybrid vehicles. It can effectively ensure smooth power output between the engine and the motor; Reduce the vibration and impact caused by torque fluctuations or speed changes in the power system, and enhance the driving experience; When the torque exceeds the design range, prevent system damage by slipping.

WGY608 is a recommended friction material for high horsepower clutches in commercial vehicles. It uses aramid fibers to improve the heat resistance and wear resistance of the skeleton material, thereby achieving sustained and stable power output under high horsepower conditions; Combined with NANMO's high wear-resistant formula material, it is a friction material with excellent service life and thermal stability.

WGY908 is a recommended friction material for high horsepower clutches in commercial vehicles. It uses high content aramid fibers to improve the heat resistance and wear resistance of the skeleton material, so as to obtain a sustained and stable friction coefficient under high temperature, high energy density and other working conditions, ensuring power output; Combined with NANMO's high wear resistant formula material, it is a friction material with excellent service life and thermal stability.

WDK510B is a friction material recommended for use in commercial vehicle clutches. It applies pre oxidized fibers to improve the thermal stability of the skeleton material, thereby achieving smooth power output, reducing vibration and impact caused by torque fluctuations in the power system, and enhancing driving experience; Combined with NANMO high wear resistant formula material, a friction material with excellent service life and thermal stability is obtained.

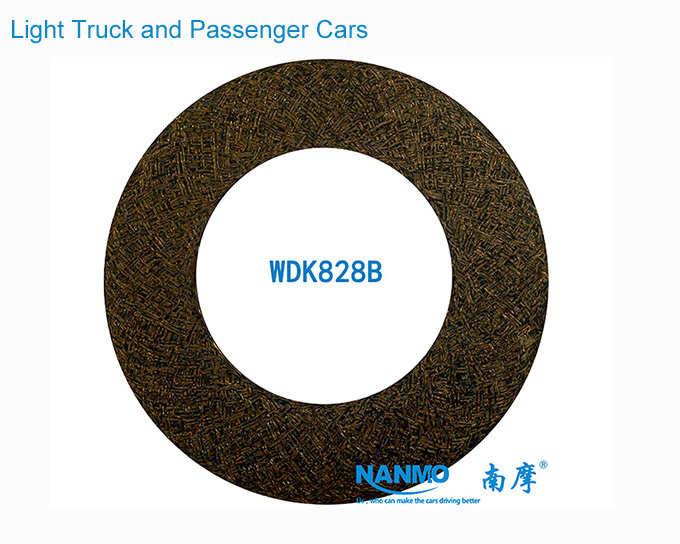

WDK828B is a product that improves thermal conductivity efficiency by adding copper wire based on WDK828. It is also used as a friction material for passenger cars and light trucks. It utilizes high-performance polymer materials to achieve excellent thermal stability and driving comfort. Ensure smooth power output during start-up, climbing, reversing, and other situations.

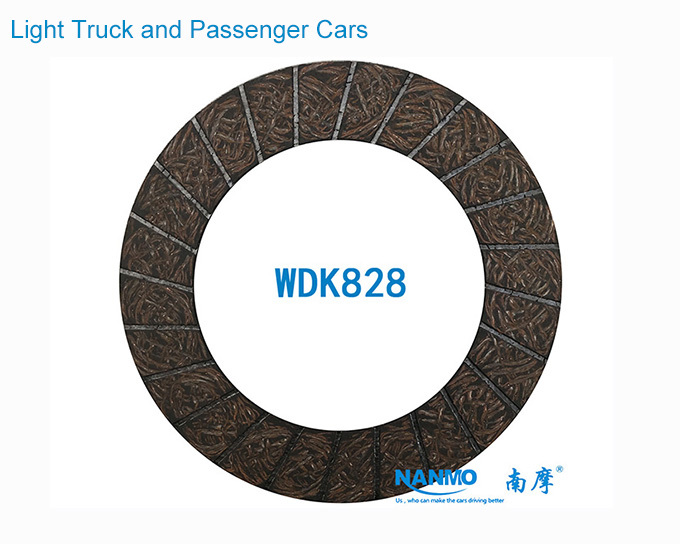

WDK828 is a main engine matching friction material used in passenger cars and medium and light trucks. It utilizes high-performance polymer materials to achieve excellent thermal stability and driving comfort. Ensure smooth power output during starting, climbing, reversing, and other situations.

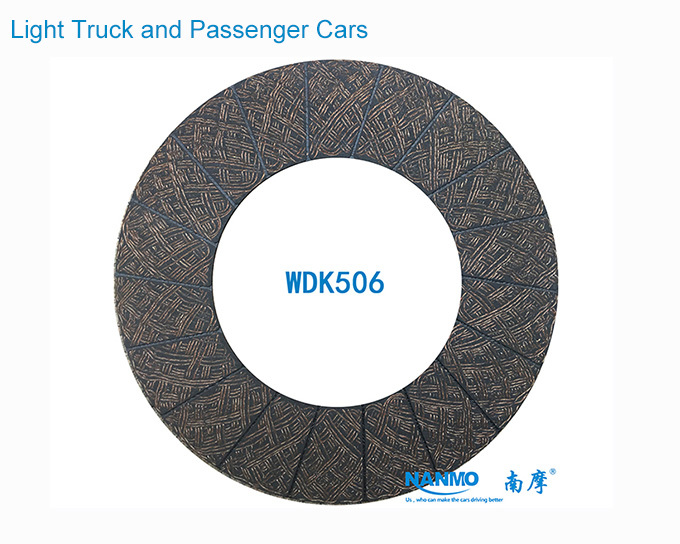

WDK408A (ameliorating) is a recommended friction material for the automotive clutch aftermarket. It uses high-strength composite fibers as the skeleton material, combined with NANMO's high-performance formula, to achieve smooth power output. It is a friction material that can be applied to clutches of various vehicle models, with excellent cost-effectiveness and market adaptability.